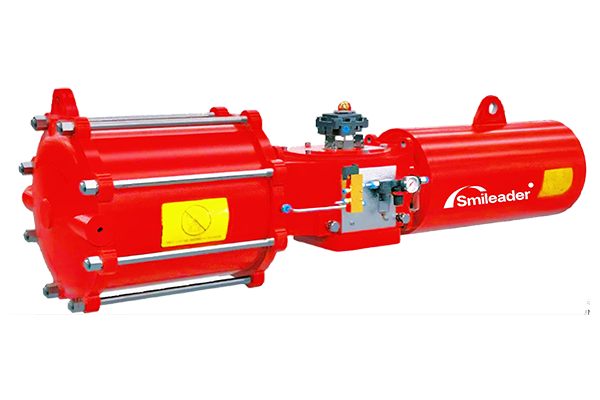

VG series high torque angular stroke pneumatic actuator

Unique advantages optimize module design with high strength and compactness

Introduction

Wear resistance and corrosion resistance

The internal piston rod, guide rod, and self-lubricating bearings of the VG series heavy-duty fork pneumatic actuator have undergone excellent surface treatment. The guide slider is made of high-performance aviation aluminum material, organically combined to effectively eliminate lateral loads. The sliding components are wear-resistant and stable; The surface of the body is sprayed with high-tech protective coatings, and the inner wall is coated with polytetrafluoroethylene, which can meet the requirements of metallurgical, petrochemical, sewage treatment and other working conditions.

The VG series heavy-duty fork pneumatic actuator adopts a lateral independent manual device, which is an important component of valves or actuators. Zhuoke self-control has multiple manual operation modes to meet different working conditions. Such as: screw, gear, clutch gear, hydraulic manual, etc.

Waterproof protection

The VG series heavy-duty fork pneumatic actuator meets the protection standards of IP66 and P67. Each component connection is equipped with high-performance O-rings and sealing gaskets to ensure that external moisture and pollution dust will not enter the interior of the actuator. The performance is stable and reliable, and the service life is longer. Diversity control

Womi has extensive experience in pneumatic control. Pneumatic control systems are an important component of valves and actuators, designed to meet customers' requirements for switching, regulation, and emergency shut-off. The pneumatic system of the VG series heavy-duty fork pneumatic actuator can be installed on a panel or control box, and can be mounted on the actuator or placed separately.

The actuator output accessories comply with the NUMAR standard, and the valve connection size standard meets the requirements of ISO5211. Conventional universal components such as seals and fasteners are implemented in accordance with international standards, making the ZKG series actuators have good universality and maintainability.